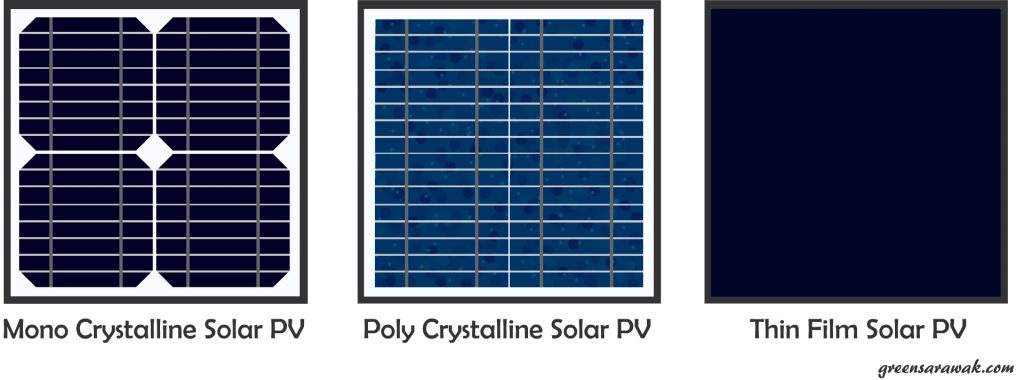

Types of solar PV cell

There are many different types of solar PV cells in the market, but mainly divided into three main types.

- Mono-Crystalline Silicon Solar PV (Monocrystaline Solar Cells)

- Poly-Crystalline Silicon Solar PV (Polycrystaline Solar Cells)

- Thin-Film Solar Cells (TFSC)

More information about each cell types can be found in our another article: Photovoltaic – Harvesting the Power of the Sun.

In the consumer market, most of home solar PV panels are of either Mono-Crystalline or Poly-Crystalline type. Both of these solar PV cells are very well established in the market and cost have been dropped down to nearly $0.30 per watt and widely affordable.

The Mono-Crystalline being the highest purity silicon solar PV cells that are manufactured from a single large artificially grown silicon crystal are known to perform better than the Poly-Crystalline counterparts. In recent years, there is improvement in manufacturing process and coatings, making both crystalline are quite closely matched in competition , with Mono being slightly ahead in efficiency but more costly. Mono-Crystalline also performs marginally better in warm temperature and low light.

Solar PV cells are being manufactured by different companies all around the world. Currently China produced solar PV cells are dominating the market. China is the world’s largest producer of photovoltaic power since 2015 until today and continue growing.

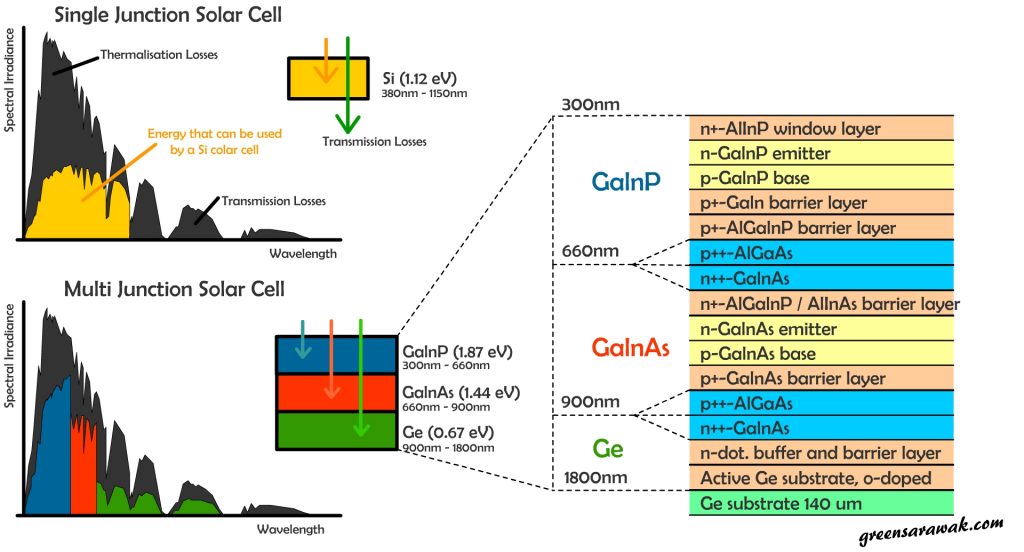

The Efficiency of Solar PV cell

It is important to know that there is no 100% efficient solar PV panels out there. Normal commercially available solar panel is of single junction silicon variety (both mono and poly crystalline PV) can only have a maximum 33% of efficiency under standard test condition. It is called the Shockley Queisser Efficiency Limit. The limit is mainly due to the fact that not all photons from the sun lights are captured, lower energy photons are not absorbed, higher energy photons are absorbed but excess energy loss as heat. Actual efficiency of solar PV will have lower efficiency than 33% due to resistance of wires, internal reflection from the glass and solar PV surface, space occupy by electrodes on the silicon PV surface and heat induced resistant in semiconductors. Thin film PV with different material than classical silicon, and newer panels with multi junction “stacking” will have higher theoretical efficiency.

Showing how the two cells perform in converting the full spectrum of sunlight into electricity. In single junction silicon solar cell can accept photon with energy level more than 1.12eV, any energy more than 1.12eV is wasted as heat. In multi junction solar cell, different semiconductor can harvest photon of different energy level, hence increase the total efficiency.

When comparing solar PV of similar rated wattage between two different types (e.g mono vs poly), you must know that both same wattage rated panels will produce near similar power, but lower efficiency panels (e.g. poly) will be larger than higher efficiency panels (e.g. mono). If space is not an issue, poly crystalline being a cheaper can be a good choice for consumers.

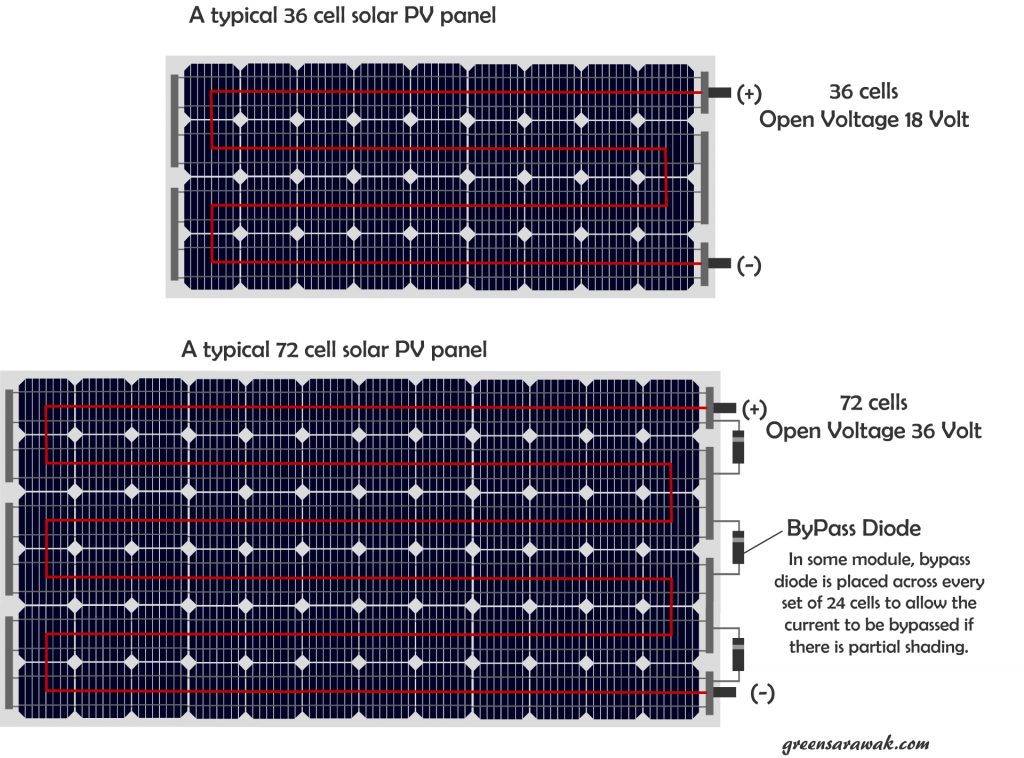

Nominal Voltage of a solar PV panel

The term “Nominal” is regarded as a de facto value or generally accepted estimation which usually groups according to its purpose for easy identification and classification. It is different from “real” value which had a exact value. Example in home power line, it can be of 120 Volts or 240 Volts nominal system, but the actual value can be varies between ±5-10% depends on load, power generation capacity, and other factors.

We also use Nominal voltage to categorize battery-based solar equipment. Because a higher voltage is required to charge a battery. The two common nominals used in battery-based solar PV systems are 12 Volts and 24 Volts. To easy classify the solar PV panels we always say this is a 12V panel or a 24V panel.

A 36 cells nominal 12V panel actually has a Voc (open circuit voltage) voltage of around 22V, and a Vmp of around 17V. Double that up, a 72 cells nominal 24V panel actually has a Voc voltage of around 44V, and a Vmp of around 36V.

Other variant such as 32 cell solar PV panels that have open voltage of close to 14.7-15 volts, which benefits direct charging of lead acid battery till its full capacity. A 48 cell solar PV panels will have open voltage of 22 volts, in which a charge controller is needed to prevent overcharging of a 12 volts battery.

In grid-tied system or MPPT charge controller, nominal volts is of less importance, instead a open circuit voltage is considered. This is because you can series up few panels and run a MPPT or grid-tied system at a higher voltage (e.g 45V,150V,600V).

Things to note behind a Solar PV panel

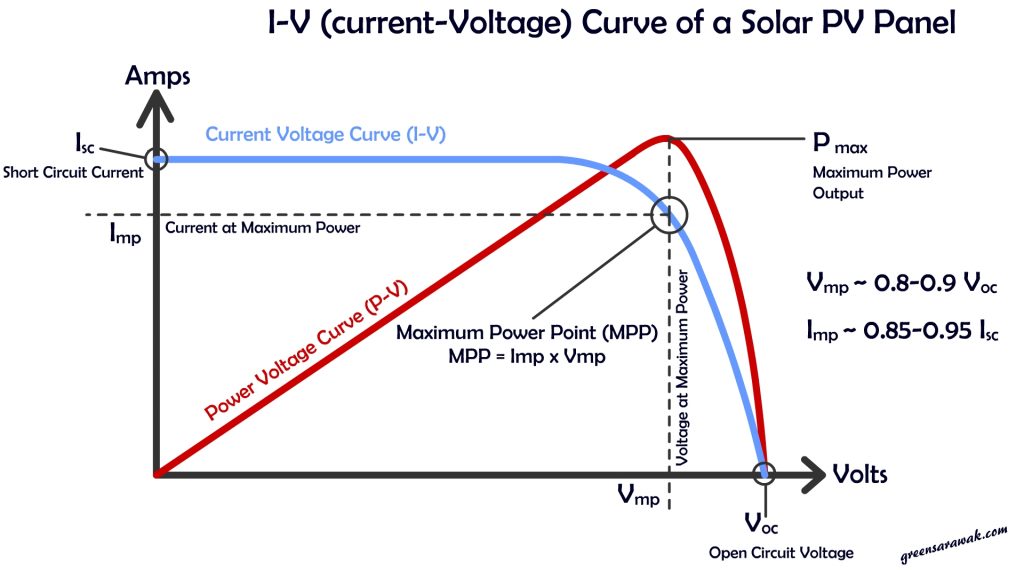

Open Circuit Voltage (Voc) is the highest voltage that the solar PV panel can produce in a Standard Test Condition, without any load to the panel (hence open circuit). This Voltage can be higher or lower depends on temperature different from the Standard Test Condition of 25 degree Celsius.

The Voc will be important when come to choices of inverters and charge controller, you don’t want risk to damage the delicate electronic devices with panels that can produce higher voltage that recommended range, especially when you decided to series the panels to produce higher voltages.

Since the Voc varies with temperature, you might need take in consideration for extra voltage generated in cooler weather (e.g. winter) than standard test conditions. Try to look around for data sheet that have graphs that mention Voc in several different temperatures, take note on the lowest temperature that your area might encounter into your calculation to make sure it is not over the recommended voltage input of inverters and charge controllers.

Short Circuit Current (Isc) is the highest amperage (current) that the solar PV panel can produce by creating a short circuit (via connecting a Amp meter directly across the panel output).

This corresponding to the maximum current that can pass through the solar cells at a standard test condition. When choosing multiple solar PV panels to place in series, it is important to makes sure the Isc is similar to prevent the panel with lower Isc to be overloaded (short circuited) when working together with other higher amperage panels.

Voltage at Maximum Power (Vmp) is the voltage the solar panel is at when it is producing the most power.

Current at Maximum Power (Imp) is the the current output where the solar panel is producing the maximum amount of power.

Both Vmp and Imp is taken into calculation of maximum wattage of your panel under a standard test conditions.

Solar Panel performance can be explained with a current-voltage curve. It can also be found in the manufacturer data sheet.

It started at the Short Circuit Current (Isc) where the current is maximum but voltage is zero. Subsequently the current stays the same with voltage raises, up to a point where further voltage raises will show as current drop, until it reach Open Circuit Voltage (Voc) with zero current flow. The sweet spot is the maximum power point corresponding to the Voltage at Maximum Power(Vmp) and Current at Maximum Power (Imp).

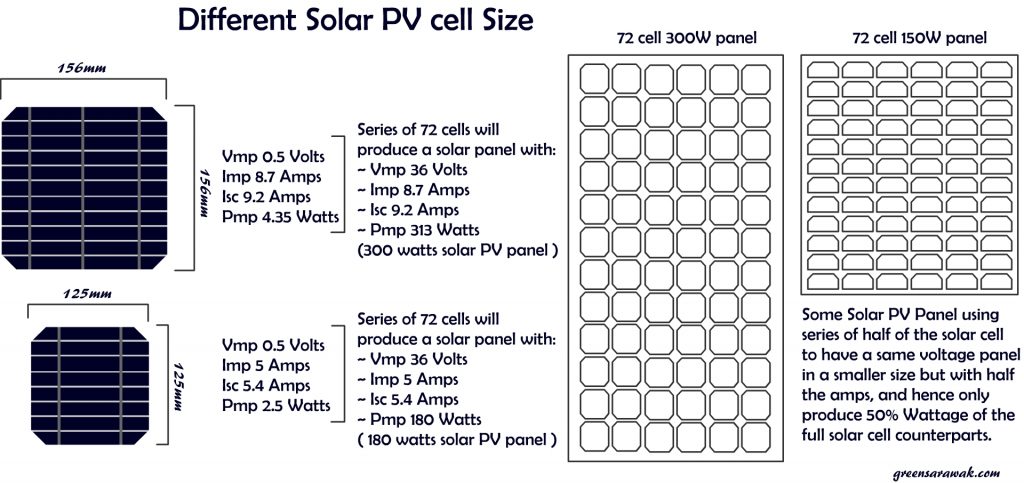

Solar PV cell size and solar PV panel output

A solar PV panel is a assembly of solar PV cells that are placed in series. Each solar cell can typically have a open voltage (without any load) of 0.5 Volt (~0.46V) potential difference with a short circuit current of 3 amps. However it will be differ depends on the size of solar wafer used. A smaller solar PV will have lower amperage rating due to less semiconductor area for current to pass.

Occasionally we can see smaller panels with tightly packed half solar cells (rectangular shape cells instead of square shape cells). These panels are aim to have higher voltage output with a smaller form package, but a reduced amperage and hence lower wattage.

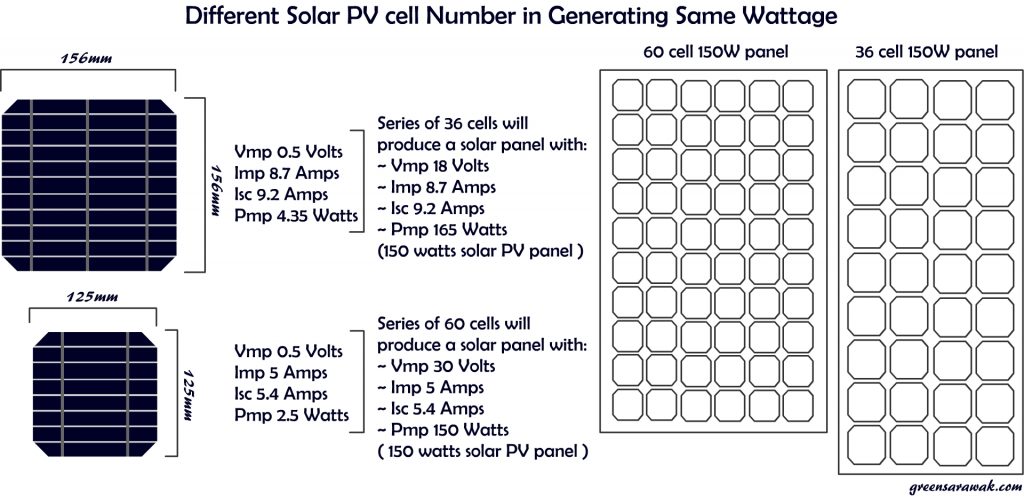

At times you might come into two same wattage panel but different cell size and count. Panel will small cell size will have more cell count (hence higher voltage lower amperage) in compare to panel with larger cell size with lower cell count (hence lower voltage higher amperage). A lower cell count panel is usually panels for system with lower nominal (e.g. 36 cells is for 12 volt nominal system, while 60 cells is for 20 volt nominal system). In fact the surface area of the two is nearly identical for two panels with same wattage.

Other than the two standard solar PV size mention above, there are also other sizes available, depends on surface area available for solar contact and required nominal voltage for operating. Solar wafer can be sliced into different sizes as required.

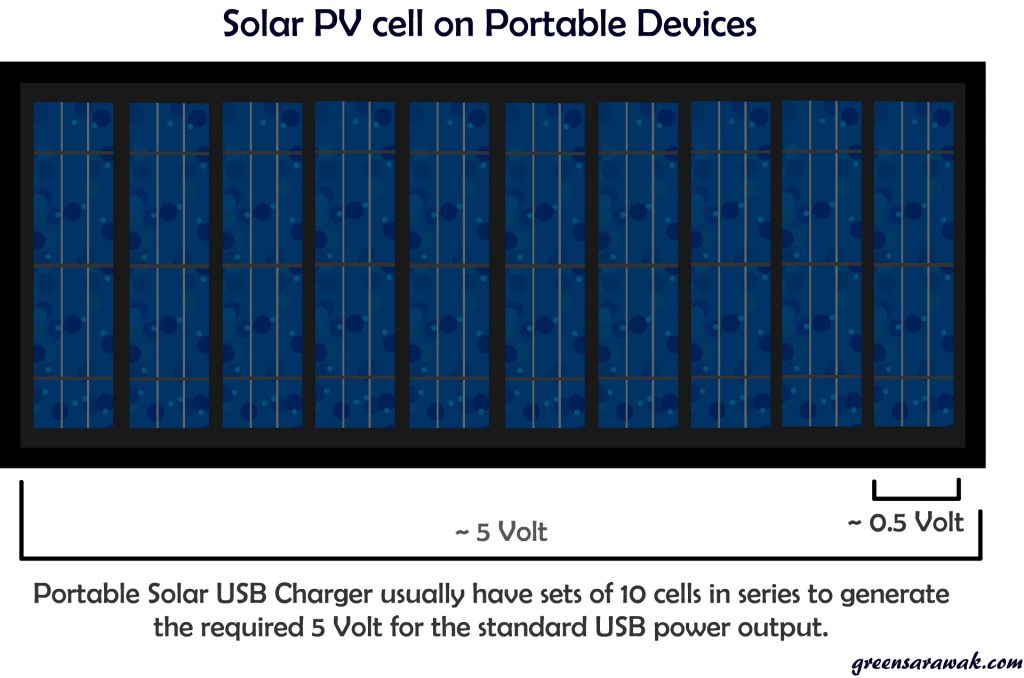

In portable devices, the nominal voltage is 5 Volts, which is the nominal voltage for USB connectors. Hence to effectively generate 5 volts nominal, the required cell count will be 10 (as 0.5 volts each cell). However having 10 normal cells will occupy large surface area, and hence for portability, the cell size is much reduced, and hence the amperage is also much reduced. Remember, each cell will generate ~ 0.5 volts irregardless of size, but smaller size will allow lower amperage, and hence low wattage panels. A good example is a portable USB battery bank with attached solar panel.

Selecting a Solar PV panel

When selecting a solar PV panels, it is important to select a quality panels as a good solar PV panels will continuing to produce power even after few decades. Some of the solar PV panels that were in use since 40 years ago are still continue to produce power today. The common fails in solar PV panels are degrading panel frames and degrading solar PV cells that do not seal properly causing water and moist to enter the silicon cells.

Since solar PV panels last very long, hence it is considered one of the best renewable resources available. It can have return of investment in few years time in terms of electricity cost. More importantly the zero carbon emission during functioning throughout its service life can “compensate” the initial energy cost to manufacture it in a few years time. (The upstream process of manufacturing a solar PV system will generate 80%-95% of the emission in a solar PV lifecycle, with carbon footprint estimate 12g per kWh for a facility using thin film and 24g per kWh in crystalline silicon panels. It is not carbon emission free to start with but in the long run it is still better than continuing burning fossil fuel in power generation.)

A good solar PV panels will obviously comes with a good warranties which can be either of performance guarantee or equipment guarantee. A performance warranty will typically guarantee 90% production at 10 years and 80% at 25 years. A equipment warranty will typically guarantee 10 – 12 years without equipment fails. This protect the consumers from problems such as manufacturing defects and premature wear and tear.

A good solar PV panels will have a quality frame and protecting glass. The frame is commonly made of anodised aluminum which is durable and corrosion-resistant. The glass in front of the panel is usually tempered glass that resist break under stress. The solar PV cells is usually tightly packed and sandwiched to prevent leaking of air and moist that can corrode the electrodes on the cells.

A good solar PV panels is important as it will sit on your roof or outdoors under sun and rain for decades and yet need to meet the power generation expectation without troubles for decade. Moreover a faulty panels will affect the overall efficiency of your solar PV system. The return of investment in solar PV is in term of electricity generation, hence fast degrading panels will reduce the actual return of investment.

NEXT CHAPTER >> Know Your Solar PV Cells performance under the heat